Confined spaces can present a number of hazardous working conditions, particularly where construction is involved. Each year in the UK, many people are killed or seriously injured while working in such spaces – or attempting to rescue others without the proper training and equipment.

Put simply, working in confined spaces can be dangerous. For those involved in the planning phase of a construction project, it’s vital that any potential risks of working in confined spaces are properly outlined and that staff are aware of the precautions they must take when doing so.

To help you out, we’ll look at confined spaces in more detail, investigate the risks involved, the legal requirements surrounding them, and how you and your team can approach working in and around confined spaces wherever they might be involved in your next construction project.

What is a confined space?

While it’s not possible to provide a truly comprehensive list of confined spaces, they can generally be defined as any space of an enclosed nature where a risk of death or serious injury from hazardous substances or dangerous conditions such as the following:

- A lack/excess of oxygen

- Excessively high temperatures

- The presence of flammable or explosive atmospheres

- Harmful gas, fumes or vapours

Certain confined spaces can be easy to identify, such as enclosures with limited openings (storage tanks, silos, sewers, etc), whereas others may be less obvious, but just as dangerous, such as open-topped chambers, ductwork, combustion chambers and even unventilated or poorly ventilated rooms.

Over the course of work being carried out, certain places may become confined spaces as a result of construction, fabrication or subsequent modification.

What are the risks of working in confined spaces?

The dangers and hazards of working in confined spaces can arise as a result of the following issues:

Toxic atmospheres: Where the presence of hazardous substances may be present, the impairment of judgment, unconsciousness and even death may occur. Such substances may be present in confined spaces for a number of reasons including:

- Remnants from previous storage

- The disturbance of sludge and other deposits

- The presence of fires within the space

- Through various work processes carried out in the space

Oxygen deficiencies: A lack of oxygen may occur as a result of:

- A reaction between soils and the oxygen in the atmosphere

- The action of groundwater on chalk and limestone. This produces carbon dioxide and can displace normal air

- Rust formed on the inside of steel tanks and vessels

Oxygen enrichment: Conversely, an excess of oxygen can also pose problems. Too much oxygen in the presence of combustible materials can result in an increased risk of fire and explosions. You should be mindful of other materials which do not burn in air; these may burn more readily – or even spontaneously – in the presence of excess oxygen.

Flowing liquid or free-flowing solids: Liquids or solids can flow into the confined space and cause drowning, suffocation, burns and other injuries. Solids in the form of powder can also be disturbed in a confined space, creating an asphyxiating atmosphere as a result.

Excessive temperatures: In such an enclosed space, excessively high temperatures can increase the risk of heatstroke or collapse from heat stress, both of which can be made worse through personal protective equipment or through a lack of ventilation.

Where construction is concerned, certain risks of confined spaces may arise as a result of the work being carried out over the course of a project, such as:

- Ineffective isolation of a nearby plant causing leakage from a pipe connected to the confined space

- Gas, fumes or vapours caused by welding, or through the use of volatile and flammable solvents and adhesives

- If access to the space is through a restricted entrance, such as a manhole, then escape or rescue in the event of an emergency may be obstructed

What are the legal requirements of working in confined spaces?

Under the Confined Spaces Regulations 1997, employers and employees must adhere to the following duties:

- Avoid entry to confined spaces by doing the work from the outside

- If entry to a confined space is unavoidable, follow a safe system of work

- Put in place adequate emergency arrangements before the work properly begins

Two years later, The Management of Health and Safety at Work Regulations 1999 required employers and the self-employed to carry out the necessary risk assessments for all work activities in order to decide what measures are needed for safety, including in confined spaces.

Working safely in confined spaces

At the planning stage of construction, you’ll need to identify potential risks and put in place precautions so the need for working in confined spaces can be reduced. As per the first duty of the Confined Spaces Regulations 1997, the team should avoid entering the space entirely and carrying out the work from outside. This can be done using a series of tools and measures, such as:

- Clearing blockages by using remotely operated rotating flail devices, vibrators or air purgers

- Inspecting, sampling and cleaning done from the outside using specialised equipment and tools

- Using remote cameras for internal inspection of especially confined spaces

Safe systems of work

If avoiding entry to the confined space isn’t possible, then you must have a safe system for working inside the space prior to construction. After carrying out your risk assessment (HSE’s page here can help), use your results to identify what you need to do to reduce the risk of injury.

Your safe system of work, including the precautions you’ve identified, must be communicated across construction teams and lab staff, while personnel will also have to be properly trained and instructed so they remain as safe as possible.

In preparing a safe system of work, you should consider the following:

- Appoint a supervisor

Supervisors will be responsible for making sure that precautions are taken, safety at each stage is checked and remaining present while work is underway, if necessary.

- Are people suitable for the work?

Do personnel have the right experience for carrying out the work? You may also need to factor in things such as claustrophobia or fitness to wear breathing apparatus too.

- Isolation

Mechanical and electrical isolation of equipment will be needed if it could otherwise operate inadvertently. Be sure to check ahead of work that isolation is effective.

- Check the size of the entrance

Is the entrance large enough to accommodate workers wearing bulky equipment entering and exiting the space? You’ll also have to weigh up ready access and exit in case of emergency.

- Ventilation

Suitable ventilation within the workplace is a must. You may need to increase the number of openings, or provide mechanical ventilation to ensure an adequate supply of fresh air.

- Special tools and lighting

Non-sparking tools and protected lighting will be required wherever flammable or potentially explosive atmospheres are likely.

- Breathing apparatus

If gas, fume or vapour is present, or the space is deficient in oxygen, then breathing apparatus is required.

- Emergency procedures

The emergency procedures you put in place before work begins ensure that you’ll have the appropriate arrangements for carrying out rescue operations should an emergency take place.

You’ll have to consider:

- An effective means of communication for raising the alarm, both from within the confined space and by someone outside

- The provision of rescue and resuscitation equipment

- The shutdown of any adjacent plants before attempting emergency rescue. In doing so, you must ensure access and a safe means of shut down is available

- Making contact with local emergency services in order to make them aware of the incident. Planning out access to the space will have to be mapped out ahead of work, while emergency services will also have to be made aware of any dangers within the space upon their arrival

You should also identify specific personnel as rescuers. Those on your team who are rescuers must be:

- Ready and available

- Fit to carry out the task

- Equipped with the necessary PPE

- Capable of using any equipment they need to carry out the rescue, such as breath apparatus, fire-fighting equipment and lifelines.

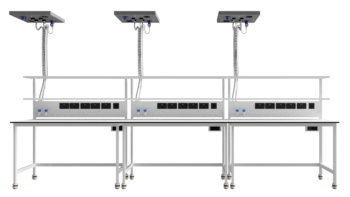

Need to complete that upcoming construction project? The team at InterFocus can help with that. For more information about our bespoke fitted labs, visit our homepage or call our team on 01223 894 833.