Used in a wide range of applications, laboratory ovens cover a selection of sciences, necessary for a variety of industrial, research and development purposes. Here, we’ll guide you through the various uses of these essential bits of equipment.

The Laboratory Oven: An Overview

The most commonly found laboratory ovens range in temperature from ambient to around 300°C, used in the fields of chemistry, biology, pharmaceuticals, and forensics. Ovens that operate above 300°C are traditionally used for more specialised applications in physics, electronics and materials processing.

Quick Navigation

Types of Lab Ovens

-

Heavy Duty Ovens

Used in industrial applications, these robust ovens are bolstered with heavy duty fittings and furnishings to stand up to their drying and curing usages.

-

Standard Digital Ovens

Built for general purposes such as heating and drying, standard digital ovens are built to offer accuracy, control and safety.

-

Hot Box Ovens

Built for environments where absolute accuracy is not particularly necessary, but will appropriately bake the samples being tested.

-

Wax Melting Ovens

Used to melt and maintain wax for the purpose of histology (the study of the microscopic anatomy of cells and tissues of plants and animals).

-

High-Temperature Ovens

Custom built to meet the specifications needed by its respective labs, high-temperature ovens are made with additional insulation to their doors and cabinet walls, since they employ temperatures upwards of 500°C. Used extensively in the aerospace industry.

The Uses of Lab Ovens

-

Annealing

The process of annealing involves heating and then cooling material, such as glass or steel, in order to reduce hardness and increase ductility. High-temperature ovens are used in this process, often in the application of metallurgy, medical device manufacturing and material science industries. These annealed materials can be cut and shaped more readily to be used in the production of things such as syringes and catheters.

-

Die-bond curing

Through a combination of drying and baking, lab ovens cure substances in order to harden their chemical composition. This is a means of creating epoxies, glues, plastics and rubbers used in polymer research, nanotechnology and semiconductor industries. The increased bond strength is also exceptionally useful in adhering components directly onto circuitry, many of which are used in military, space and medical systems.

-

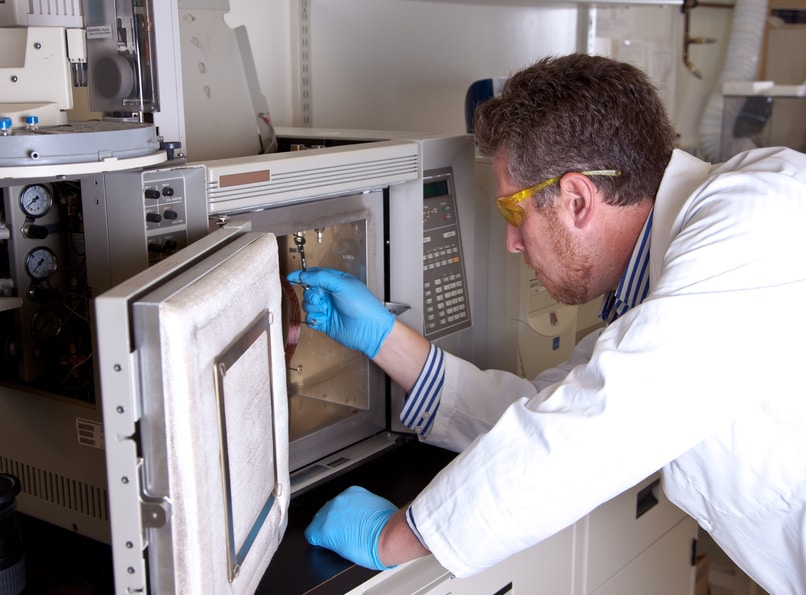

Drying

A necessity for many environmental, biological and clinical labs; gravity convection, forced air and vacuum ovens are used in the drying of samples to remove moisture from them.

Forced air and vacuum ovens are best suited to samples that are easily broken down, as these remove moisture and lower the boiling point of water, letting the sample to be dried at a lower temperature.

Gravity convection ovens, meanwhile, are often used to dry fine particles as these are liable to scatter with high air flow and need a more natural airflow in order to protect these delicate samples.

-

Polyimide baking

Added to the oven in liquid form, the polyimide is then thermally baked to create a thin film or a layer for various uses, including stress buffer coating for redistribution layers, adhesion, chip bonding and much more.

-

Sterilising

At their most basic, laboratory ovens can also be used to sterilise lab equipment and glassware. Carried out in a hot air oven, the ideal temperature needs to be at least 160°C, with contents monitored at this heat for 45 to 60 minutes.

A slow cooling period is needed, as removing items from the oven straight away can cause them to crack, while the gradual cooling prevents potentially harmful air, containing contaminating organisms, from entering the oven.

Additionally, all items that need to be sterilised also have to dry – using a temperature of 60°C is thought to be acceptable when routinely using glassware.

Additionally, lab ovens are employed to perform material testing, analysing attributes such as determine tensile strength, deformation and resiliency of manufactured products, solder strength in circuit boards and more.

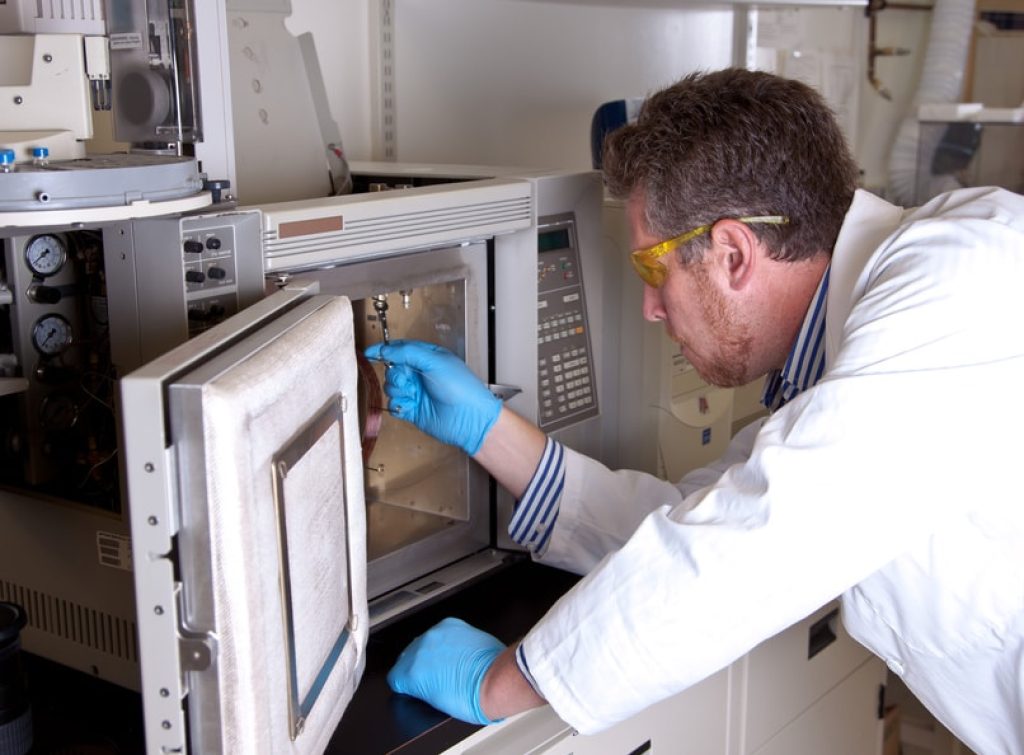

Lab ovens are also used in biological, forensic and environmental labs where their uses are more specialised. In forensic labs, specially configured vacuum ovens are used to develop fingerprints, while biological labs use gravity convection ovens to remove microbiological contaminants in lab equipment, along with vacuum ovens in order to adhere substrates to the surface of filters. Elsewhere, environmental laboratories weigh specimens before and after drying to determine their moisture content.

Enjoyed this article? There’s plenty more to be found over on the InterFocus blog. Looking for information on our bespoke fitted labs? Visit our homepage or call the team on 01223 894 833.