Whether it’s in specialised devices like autoclaves and centrifuges or everyday equipment such as computers or light fixtures, the electricity required by laboratories isn’t exactly in short supply. And when it’s used in such a wide variety of items, it can easily become a hazard if the equipment becomes damaged or is used improperly.

Faulty equipment, overloaded circuits and other hazardous electrical conditions present a serious safety risk and can cause incidents and injuries if left ignored. To ensure your laboratory is free from electrical hazards, understanding the dangers of such threats and how your staff can protect themselves is critical.

Here, we’ll take a closer look at electrical safety in the lab so that you and your colleagues remain safe and compliant while carrying out their duties.

Quick Navigation

- What are the hazards of electricity?

- Electrical safety risks in a lab

- What are the basics of electrical safety?

- Rules for working with electrical equipment

What are the hazards of electricity?

In a laboratory environment, electricity can create the following hazards:

- Electric shock

- Electrocution

- Burns caused by either electrical or thermal contact

- Fires

- Explosions

- Indirect injuries such as cuts and lacerations

How does electric shock occur?

Electric shock occurs when the body becomes part of an electrical circuit; electrical current enters the body at one point and leaves at another.

Electric shock generally occurs in one of three ways. Individuals, in contact with the ground, then come in contact with one of the following:

- Both wires of the electric circuit

- One wire of an energised circuit and the ground

- A metallic part that has become “hot” through contact with an energised conductor

A shock’s severity depends on three main factors:

- The path the current takes through the body

- The amount of current flowing through the body

- The length of time the body is in contact with the current

While minor shocks may be barely noticeable, more serious instances can result in cardiac arrest, burns, tissue damage or even death. When death by electric shock occurs, it’s known as electrocution. Don’t make the error of confusing the term with electric shocks – there’s a big difference!

Electrical safety risks in a lab

Electricity and flammable liquids

Making sure these two hazards don’t come into contact is imperative. If any kind of electrical shock occurs near these liquids, fire can spread very quickly, while larger amounts of liquid can cause explosions.

Electric shocks can come from wires, electrical outlets, capacitors and other sources, so it’s important to routinely test such equipment to ensure they remain in full working order.

Ground faults

Ground faults occur when there is a break in the grounding path from a tool or electrical system. The electrical current may then take an alternative path to the ground through the user, which can result in serious injury or death.

Ground fault current interrupter (GFCI) outlets act like circuit breakers, shutting off electric power in the event of a ground fault. However, if the grounding conductor isn’t intact or is low-impedance (i.e., has only a low resistance to A/C current), shocks can still happen – so your GFCIs must be installed properly.

Arc flashes

Most electrical faults are capable of producing sparks or arcs. Brief, small arc flashes are called sparks and are generally harmless, but sustained arc flashes with more energy can be powerful and dangerous, causing shocks, burns, explosions and even dangerous amounts of UV radiation.

Certain arc flashes are so powerful they can throw employees backwards through sheer force, causing indirect injuries such as sprains, fractures and lacerations, as well as causing harm to anyone working nearby.

If there is potential for arc flash hazards in your lab, such as with electrical service panels or capacitor banks, then the equipment should either be guarded to prevent hazards during normal operation or isolated to areas that only trained and authorised personnel can access.

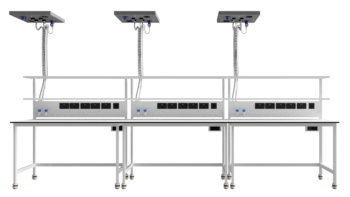

Extension cords

If you have a lot of equipment but a shortage of outlets, then you might need to use extension cords and power strips. These are safe to use when done so correctly, but they carry their own hazards.

For instance, they must be rated to carry sufficient amperage for the device, or it may overheat, damaging the equipment and putting employees at risk. They’re also prone to wear and tear, leading to faulty connections, exposed wires and short circuits through overuse.

Power strips create additional outlets on an existing circuit. While this is convenient if you have many low-amp devices in one area of your lab, plugging too many devices into one circuit can cause overheating.

Likewise, plugging multiple extension cords or power strips into one another increases the distance that energy must travel. This raises the resistance in the system, increasing the likelihood of overheating.

Not understanding the dangers of electricity

Unfortunately, some people in laboratory environments simply don’t understand just how dangerous electricity can be. Despite their size, lower-level systems used in a range of lab equipment can still cause serious incidents.

It only takes between nine and 30 milliamps of current to cause someone’s muscles to freeze up. If they’re holding the source of the shock, then the circuit will remain unbroken, causing serious problems as a result.

What are the basics of electrical safety?

Wear the appropriate protection

Perhaps the most important thing you can do to protect yourself and those around you when working on electrical systems is to use the correct personal protective equipment. There are many types of PPE specifically designed to keep you safe against electrical hazards, so make sure you’re minimising any potential risks when using the equipment.

Use lockout/tagout

If you have any high-voltage systems in your lab, then always enact the lockout/tagout system. Using this system stops the unexpected start-up of equipment and machinery.

Lockout refers to the placing of an actual lock or physical block on the circuit breaker, switch or other control. Tagout, on the other hand, allows a tag to be placed on equipment or controls that cannot be locked out.

Perhaps the most important thing to remember when using the system is “one lock, one employee”. This is so that other employees don’t inadvertently remove the lock; each lock should be clearly labelled to identify the worker assigned to the lock.

Never take risks

Don’t take shortcuts in the name of efficiency when electricity is involved. Even the smallest timesaver can create hazards; your lab must have a set of procedures and best practices for working on any type of electrical system to avoid potential dangers.

Making sure everyone follows the standards you set out can help reduce the risk of electricity-related injuries and fatalities.

Rules for working with electrical equipment

- Turn off the power to any equipment before you inspect it. When turning off safety switches, wear insulating gloves and turn your face away from the box before pulling the handle down

- Use only tools and equipment with non-conducting handles when working with electrical devices

- All current-transmitting parts of electrical devices must be enclosed

- When checking an operating circuit, keep one hand either in a pocket or behind your back to avoid making a closed circuit through the body

- Never change any wiring when a circuit is plugged into a power source

- Never plug leads into a power source unless they’re connected to an established circuit

- Avoid contacting circuits with wet hands or materials

- Check circuits for grounding

- Do not insert another fuse of larger capacity if an instrument keeps blowing fuses. When a fuse blows, find the cause of the problem before fitting another one

- Do not use or store highly flammable solvents near electrical equipment

- Multi-strip outlets should not be used in place of permanently installed receptacles. If additional outlets are required, have them installed by an electrician

- Ensure access to electrical panels and disconnect switches are clear and unobstructed

InterFocus can help you build the perfect laboratory for you and your team. For more information about our bespoke fitted labs, visit our homepage or call our team on 01223 894 833.